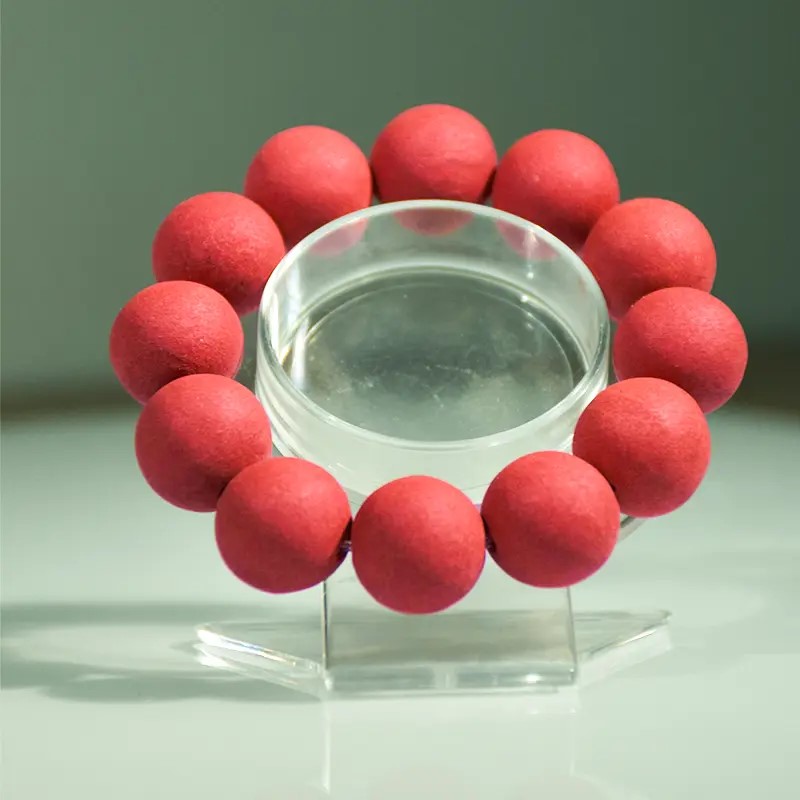

The allure of Hexiang beads lies in their captivating fusion of artistry, tradition, and aromatic science. Crafted from meticulously blended spices, herbs, resins, and woods, these fragrant orbs promise a subtle, continuous release of scent. A common assumption persists within this craft: the finer the incense powder, the better the bead. Proponents argue that increased surface area enhances scent diffusion and creates a smoother final product. However, this pursuit of ultra-fine powder is not only unnecessary but fundamentally detrimental to the very essence of Hexiang beads – their complex and enduring fragrance profile. The dogma that “finer is always better” is a significant misconception; optimal grinding for Hexiang beads lies within the 130-200 mesh range, preserving the precious volatile oils and complex aromatic compounds that define their true character.

The Science of Scent: Volatile Oils Under Siege

The aromatic magic of incense materials resides primarily in their volatile oils and oleoresins. These complex chemical mixtures contain hundreds of compounds – terpenes, esters, phenols, aldehydes – each contributing unique scent notes, from the sharp top notes of citrus peels to the deep base notes of sandalwood or the warm sweetness of cinnamon. Crucially, these compounds are delicate. They are susceptible to degradation by heat, light, oxidation, and crucially, intense physical stress.

This is where the grinding process becomes pivotal. Achieving a coarse powder is relatively simple. Reaching the functional 130-200 mesh (approximately 74-116 microns) requires more effort but is manageable with standard industrial grinders or high-quality mortar and pestle work. However, pushing significantly beyond this range – into the realm of 300 mesh (50 microns) or finer, often marketed as “superfine” or “nano” powder – necessitates extreme force. This typically involves high-pressure grinding mills, such as hydraulic press grinders or advanced ball mills operating under significant pressure.

The Pressure Problem: This high-pressure environment is catastrophic for volatile oils. The immense physical force crushes cell walls beyond simple particle size reduction. It generates significant localized heat through friction. More critically, it physically squeezes out the volatile oils and oleoresins from the plant matrix itself. Think of it like crushing an orange peel with a hydraulic press versus finely grating it – the press extracts far more oil, but in a damaging, uncontrolled way.

The Consequence: Fragrance Degradation & Alteration: The result is not enhanced fragrance, but its impoverishment and distortion:

Oil Loss: Precious aromatic oils are literally pressed out and lost to the grinding equipment or atmosphere, diminishing the overall scent potential of the powder before it’s even formed into a bead.

Compound Breakdown: The extreme pressure and heat can fracture delicate aromatic molecules. Terpenes isomerize or oxidize, esters hydrolyze. This changes the chemical composition of the scent profile. The bright, fresh top notes often vanish first, leaving a flatter, harsher, or simply “off” aroma dominated by less volatile, sometimes unpleasant, base notes. The nuanced harmony of the blend is destroyed.

Oxidation Acceleration: The vastly increased surface area of ultra-fine powder, combined with the exposure of oils during grinding, dramatically accelerates oxidation when the powder is exposed to air. This leads to rancidity and a rapid loss of the desired fragrance characteristics even before the bead is made.

Traditional Chinese Compound Incense

Traditional Chinese Compound Incense

The Delicate Art of Chinese aroma incense

Incense beads, or Chinese aroma incense beads , are far more than simple ornaments. These meticulously crafted spheres, born from the fusion of powdered precious woods, resins, herbs, and binding agents, represent a unique intersection of ancient Chinese fragrance culture, artistry, and contemplative practice. beads

The Optimal Range: 130-200 Mesh – Where Science Meets Craft

The 130-200 mesh range represents a scientifically sound and practically validated sweet spot for Hexiang bead production:

- Adequate Surface Area: This fineness provides sufficient particle surface area for the binding agents (like natural gums or honey) to effectively coat and bind the particles during kneading and forming. It also allows for adequate, controlled scent release once the bead is cured and in use. The fragrance diffuses steadily, offering longevity.

- Structural Integrity: Particles in this range interlock effectively, contributing to the mechanical strength and durability of the finished bead. Ultra-fine powders can lead to overly dense beads that may crack during drying or lack internal cohesion.

- Volatile Oil Preservation: Crucially, achieving this fineness does not inherently require the destructive high-pressure methods needed for ultra-fine grinding. Careful grinding with appropriate equipment minimizes heat buildup and avoids the extreme pressure that forcibly expels oils. The cellular structures holding the volatiles remain relatively intact, protecting the aromatic essence.

- True Aromatic Expression: Powder ground to this specification retains the full spectrum of volatile compounds intended by the blend recipe. The top, middle, and base notes remain present and balanced, allowing the bead to mature correctly during curing and deliver its intended complex fragrance profile over its lifespan. The scent is fuller, richer, and more authentic.

Beyond the Hype: Deconstructing the “Finer is Better” Myth

The promotion of ultra-fine incense powder often stems from misunderstandings or commercial interests:

- Misapplied Surface Area Theory: While surface area increases with fineness, the theory ignores the concurrent destruction of the fragrant compounds residing on that surface. More surface area of degraded aroma is not beneficial.

- Visual and Tactile Deception: Ultra-fine powder feels incredibly smooth and looks impressively uniform. This sensory appeal is mistaken for higher quality, masking the underlying aromatic damage. It caters to a modern aesthetic preference for extreme refinement, often divorced from functional or qualitative superiority in this specific context.

- Marketing & “Nano” Buzzwords: Terms like “superfine,” “ultra-fine,” or “nano” carry connotations of advanced technology and premium quality. This is leveraged for marketing, creating a perceived value that isn’t supported by the actual olfactory performance for Hexiang beads. It’s a classic case of form over function.

- Lack of Traditional Precedent: Historical texts and traditional practices in Chinese incense making (Xiang Dao) emphasize careful selection, processing, and blending of ingredients. They focus on techniques like fermentation, aging, and low-temperature processing to enhance fragrance, not ultra-fine grinding. The pursuit of extreme fineness is a relatively modern, and misguided, trend.

Practical Implications for the Hexiang Artisan

Understanding this optimal range empowers the artisan:

- Equipment Choice: Prioritize grinders that offer control and minimize heat/pressure. High-speed bladed grinders often generate too much heat; stone mills or carefully used industrial grinders set for coarse-medium grinding are often better than high-pressure hydraulic mills. Mortar and pestle, while laborious, offer excellent control for smaller batches.

- Material Awareness: Different materials have different optimal grinding points and sensitivities. Resins (like frankincense, myrrh) might tolerate slightly finer grinds than delicate flowers (like rose, osmanthus) or leaves (like patchouli). Knowing your materials is key.

- Focus on the Blend & Process: Redirect energy from chasing impractical fineness towards mastering the more critical aspects: sourcing high-quality, aromatic materials; understanding scent note classification (top, middle, base); perfecting blending ratios; mastering the kneading and forming process to ensure even distribution and good bead structure; and implementing proper curing protocols. These factors have a far greater impact on the final bead’s quality and scent.

- Quality Assessment: Learn to evaluate powder quality by its scent immediately after grinding and again after resting, not just by its feel. Does it smell vibrant, complex, and true to the raw material? Or is it flat, harsh, or noticeably changed? This is the ultimate test.

Preserving the Essence of Aroma

Hexiang bead crafting is an alchemy of nature, tradition, and sensory delight. The fragrance is its soul. The relentless pursuit of ultra-fine powder, driven by misconception and marketing, directly attacks this soul by destroying the delicate volatile oils through the intense pressure and heat required. It sacrifices true aromatic richness and longevity for an illusion of refinement.

The evidence, grounded in the chemistry of volatile oils and the practical realities of grinding, is unequivocal: 130-200 mesh is the optimal range for Hexiang bead powder. Within this range, the powder possesses sufficient fineness for effective binding and controlled scent release while safeguarding the integrity of the precious aromatic compounds. This allows the bead to mature correctly and express its full, intended fragrance profile over time. Moving beyond this range is not progress; it is a fundamental compromise that degrades the very essence of the Hexiang bead. True mastery lies not in grinding finer, but in understanding and respecting the fragile nature of the aroma, focusing on holistic craftsmanship to coax out and preserve its deepest, most enduring beauty. Let the fragrance, not the particle size, be the ultimate measure of quality.