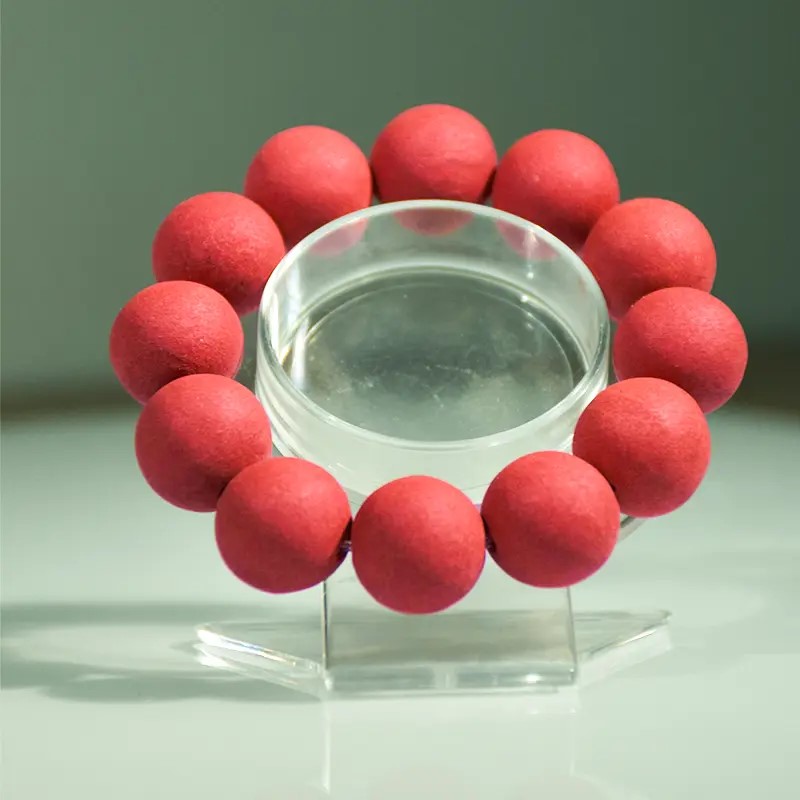

The exquisite art of crafting Aroma Incense Beads , or traditional Chinese scented beads, transcends mere fragrance. These beads, worn as bracelets, necklaces, or used for ambient scenting, represent a harmonious blend of nature’s aromatics and meticulous craftsmanship. A common concern among potential users and admirers is their physical durability: “Are Aroma Incense Beads beads strong enough? Will they shatter easily?” This question arises from a natural assumption – organic materials often seem delicate. However, a deep dive into the materials science and traditional manufacturing processes reveals a surprising truth: Aroma Incense Beads, when crafted correctly, possesses remarkable resilience and is highly resistant to breakage under normal conditions.

Deconstructing the Core: Materials and Their Roles

Understanding Aroma Incense Beads’s strength begins with its fundamental components:

- Natural Spices: The soul of Aroma Incense Beads lies in its blend of aromatic substances – woods like sandalwood and agarwood, resins like frankincense and myrrh, herbs, flowers, and seeds. While diverse, these materials share common characteristics:

- Inherent Fibrous Structure: Many aromatic woods and herbs possess natural cellulose fibers. These fibers, though microscopic, form a complex network within the bead.

- Resinous Content: Ingredients like myrrh, benzoin, or pine resin contribute sticky, viscous compounds. These act as natural internal binders and plasticizers, adding cohesion and a degree of flexibility to the matrix.

- Mineral Components: Some traditional ingredients (e.g., certain clays or calcined minerals sometimes used in trace amounts or specific recipes) can add subtle mineral reinforcement.

- The Crucial Binder: Nanmu Wood Powder

This is the cornerstone of Aroma Incense Beads’s structural integrity. Derived from the prized Phoebe zhennan (Nanmu) tree, this powder is far more than just glue.- Natural Adhesive Properties: Nanmu wood contains high levels of lignin and complex polysaccharides. When mixed with water, these compounds form a sticky mucilage with excellent binding capabilities.

- Micro-Fibrillar Reinforcement: The powder itself consists of finely ground wood particles. Each particle retains its inherent cellulose microfibrils. When integrated into the aromatic mixture, these microfibrils intertwine with the fibers from the spices, creating a dense, reinforced composite network.

- Dimensional Stability: Nanmu binder is renowned for its resistance to warping and cracking as it dries and ages, a property highly valued in traditional woodworking and furniture making – properties directly transferable to Aroma Incense Beads.

The Alchemy of Strength: The “Thousand Kneads” Process

The transformation of raw ingredients into a durable bead hinges on the labor-intensive and critical kneading process . This is not merely mixing; it’s a physical metamorphosis:

- Hydration and Homogenization: The powdered spices and Nanmu binder are carefully mixed with water. Achieving the perfect moisture level is an art – too dry, and the mixture won’t bind; too wet, and the final bead will be weak and prone to deformation.

- Mechanical Densification – “Thousand Kneads”: This is where the magic happens. The moistened mixture is subjected to prolonged, vigorous pounding, rolling, folding, and kneading. This intense mechanical action serves several vital purposes:

- Air Expulsion: Trapped air bubbles are the primary weak points in any composite material. Vigorous kneading forces these bubbles out, eliminating potential fracture initiation sites. A bead riddled with micro-bubbles would be fragile.

- Particle Alignment and Interlocking: The kneading physically forces the Nanmu powder particles, spice fibers, and resinous components into extremely close contact. Cellulose fibrils intertwine and hook onto each other, while the sticky resins flow into every microscopic crevice, gluing everything together.

- Activation of Binder: The mechanical energy and moisture help fully dissolve and activate the adhesive components within the Nanmu powder, maximizing its bonding potential throughout the mixture, not just on the surface.

- Formation of a Unified Matrix: The end result is no longer a simple mixture of powders. It becomes a homogeneous, densely packed composite material – a cohesive “dough” where the boundaries between individual components blur. This unified matrix is fundamental to strength.

Structural Analysis: Why Correctly Made Aroma Incense Beads Resist Breakage

The combination of optimized materials and the kneading process creates a bead with inherent structural advantages:

- High Compressive Strength: The densely packed composite matrix excels at resisting forces applied perpendicularly to its surface (like squeezing between fingers or light pressure against a table). The interlocked fibers and binder distribute the load effectively.

- Resistance to Brittle Fracture (Under Normal Conditions): While pure, dry spice powders might be brittle, the integrated Nanmu binder and residual resins introduce crucial elements:

- Micro-reinforcement: The cellulose fibrils act like tiny reinforcing bars within a concrete matrix, hindering crack propagation.

- Plasticizing Effect: Resins and the inherent properties of the hydrated binder add a slight degree of plasticity. Instead of shattering instantly like glass upon impact, the bead can absorb small amounts of energy through micro-deformations within its matrix before a fracture might occur. This makes it resistant to the small knocks and bumps of daily wear.

- Low Porosity: The kneading process minimizes internal voids. Fewer voids mean fewer stress concentrators and a more uniform distribution of internal forces, significantly increasing overall toughness.

- Surface Hardness: A well-made, properly dried Aroma Incense Beads develops a surprisingly hard surface. The consolidated outer layer resists scratching and minor abrasions encountered during normal handling and wear.

Defining the Limits: What Constitutes “Extreme Force”?

The key phrase in understanding Aroma Incense Beads’s durability is “non-extreme force.” While remarkably sturdy for an organic composite, they are not indestructible like metal or stone. “Extreme force” encompasses situations that would damage most non-metallic objects:

- Sharp Impacts: Being struck forcefully with a hard, sharp object (e.g., hit by a hammer, dropped point-first onto concrete from a significant height, crushed under significant weight with a concentrated pressure point).

- Severe Crushing: Sustained, immense pressure applied over a large surface area (e.g., run over by a car, crushed in heavy machinery).

- Intentional Destruction: Deliberately trying to break or cut the bead.

- Material Degradation: While not “force,” prolonged exposure to excessive moisture, extreme heat, or harsh chemicals can degrade the binder and resins over time, weakening the structure and making it more susceptible to breakage under forces it could previously withstand. This is why proper care (avoiding prolonged soaking, extreme heat, solvents) is essential for long-term durability.

Comparative Durability: Context is Key

- Vs. Loose Incense/Powders: Infinitely more durable. The composite structure binds the fragile powders into a solid form.

- Vs. Untreated Wooden Beads: Similar woods might be comparable in hardness, but the kneading process of Aroma Incense Beads often results in a denser, less porous structure than simply carving a bead from wood, potentially offering better crack resistance.

- Vs. Resin Beads (Plastic): Modern plastics can be very tough. Aroma Incense Beads won’t match the impact resistance of high-grade engineering plastics but offers comparable or better resistance to scratching and surface wear than softer resins. Its advantage is natural origin and fragrance.

- Vs. Glass/Ceramic Beads: Significantly less brittle. Aroma Incense Beads is far more likely to survive a fall onto a hard floor without shattering. It might chip or dent on a severe impact where glass would pulverize.

- Vs. Soft Clay Beads: Much harder and more resistant to deformation and chipping.

Conclusion: Engineered Resilience in a Natural Form

The concern that Aroma Incense Beads beads are inherently fragile is largely a misconception rooted in their organic nature. The traditional craft, honed over centuries, employs material science principles – specifically the use of Nanmu wood powder as a superior natural binder and the critical, energy-intensive kneading process – to engineer significant structural integrity into the beads.

The “thousand kneads” are not poetic exaggeration; they are a vital mechanical process that eliminates weaknesses, densifies the material, and creates a unified, fiber-reinforced composite matrix. This matrix provides high compressive strength, resistance to surface wear, and crucially, a degree of toughness that prevents brittle fracture under the stresses of everyday handling and wearing.

Therefore, one can confidently state: A well-crafted Aroma Incense Beads bead, made with genuine Nanmu binder and subjected to the proper kneading process, possesses substantial strength and resilience. It will not crumble, shatter, or break under normal use, accidental drops from hand height, or general handling. It is a robust artifact designed for both olfactory pleasure and practical wear. Its fragility only becomes a factor under genuinely extreme forces or through neglect leading to material degradation. Handle your Aroma Incense Beads with reasonable care, appreciate its natural beauty and scent, and rest assured of its inherent durability. The true fragility lies not in the bead itself, but potentially in the loss of this meticulous traditional craft if its techniques and material knowledge are not preserved.