Traditional Chinese Compound Incense

Traditional Chinese Compound Incense

The Delicate Art of Chinese aroma incense

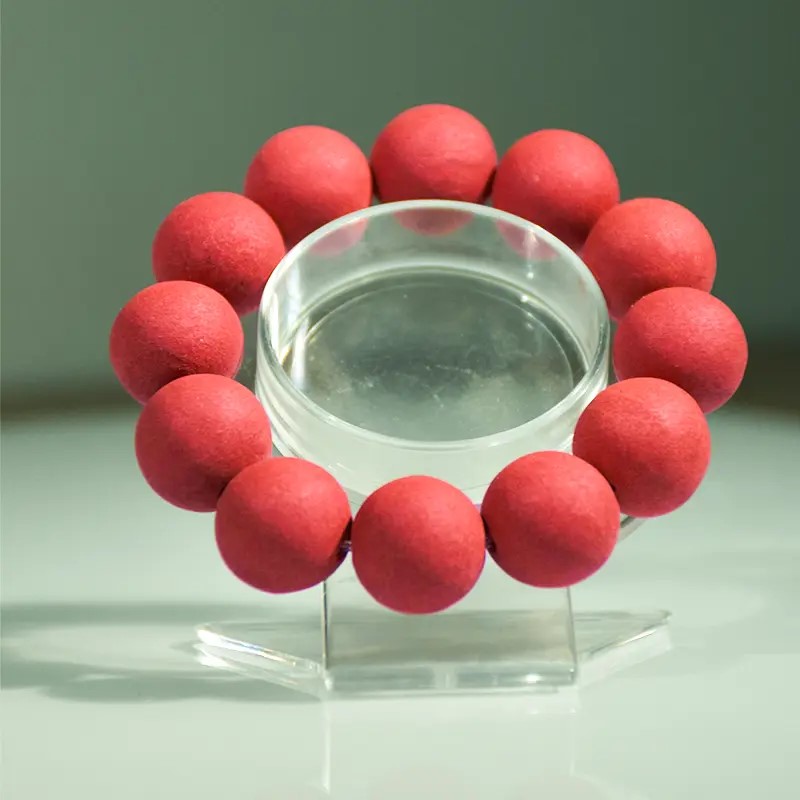

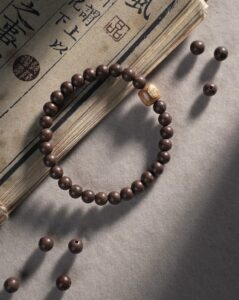

Incense beads, or Chinese aroma incense beads , are far more than simple ornaments. These meticulously crafted spheres, born from the fusion of powdered precious woods, resins, herbs, and binding agents, represent a unique intersection of ancient Chinese fragrance culture, artistry, and contemplative practice. beads

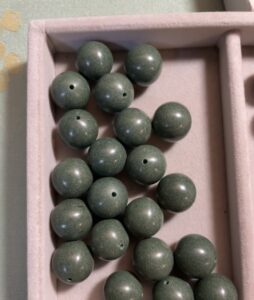

The discovery of tiny pits, pores, or an uneven surface on a cherished handmade bead can trigger immediate concern: “Is this a quality flaw?” While our instinct might equate smoothness with perfection, the reality for authentic handmade beads, especially those formed from powdered materials like incense or mineral blends , is fundamentally different. Those little craters and textures are not inherently signs of poor quality; they are often the unavoidable and natural signature of the artisan’s process. Understanding the “why” transforms perceived imperfections into marks of authenticity and craftsmanship.

I. The Science Behind the Surface: Why Pores Happen

The formation of pores and surface irregularities in handmade beads stems from the core materials and techniques:

- The Nature of Powders: Beads made from finely ground materials (incense, clay bodies, mineral pigments, herbs) start as a mass of individual particles. Even when mixed with a binder (water, oils, resins, gums), achieving absolute homogeneity where every microscopic void is eliminated is physically impossible. Air inevitably gets trapped between particles during mixing.

- The Shaping Process (Hand-Rolling/Forming): Unlike injection molding or machine pressing, human hands applying pressure cannot exert perfectly uniform, immense force across the entire bead surface simultaneously. Slight variations in pressure mean some areas compact more densely than others. Less compacted areas leave behind tiny air pockets that become pores as the bead dries or cures.

- Binder Migration and Drying/Curing Dynamics:

- Shrinkage: As the liquid binder (water, solvent) evaporates during drying, the entire bead shrinks. This shrinkage is rarely perfectly uniform due to slight density variations created during forming. Areas with slightly less binder or slightly looser particle packing shrink differently, potentially pulling away minutely and creating surface micro-fissures or emphasizing existing voids.

- Binder Flow: As the binder moves towards the surface during drying (a process called wicking), it can sometimes leave behind tiny voids internally or just below the surface, which can manifest as pits.

- Surface Tension: As the binder reaches the surface and evaporates, surface tension effects can cause slight pulling or cratering, especially around inclusions or particle clusters.

- Material Composition:

- Organic Matter: Beads containing plant materials, herbs, or resins (common in incense beads) naturally have fibrous or irregular structures. These components don’t compact like fine mineral powders and inherently create texture and potential voids.

- Inclusions: Decorative elements like small seeds, crushed petals, or mineral flecks disrupt the uniformity of the powder matrix, creating natural points where pores or irregularities are more likely to form around them.

II. Handmade vs. Machine-Made: A Fundamental Difference

This is the critical distinction:

- Machine-Made Beads (Glass, Plastic, Precision Ceramic): Employ high-pressure molding, extrusion, or molten material processes under tightly controlled conditions. These processes are designed to minimize and often eliminate surface pores and achieve near-perfect smoothness. Uniformity and flawlessness are key industrial quality metrics. Any significant pore would likely indicate a machine fault or material contamination.

- Handmade Beads (Powder-Based): Prioritize the artisan’s touch, unique material blends, and often traditional methods. The process inherently involves variables impossible to completely control:

- Human variation in rolling pressure and technique.

- Natural variations in raw material batches (particle size distribution, moisture content).

- Environmental factors during drying (temperature, humidity).

- The very nature of combining powders and binders manually.

Therefore, expecting machine-level surface perfection from a handmade powder bead is misunderstanding the craft itself. The slight irregularities are not oversights; they are the physical evidence of human creation and natural material behavior.

III. When Pores Are Normal (Even Desirable) Character

For most types of handmade powder beads, a certain degree of porosity and texture is:

- Unavoidable: As detailed in the science section, it’s a natural consequence of the process. Eliminating it entirely would require industrial techniques antithetical to handcrafting.

- Expected: Experienced artisans and knowledgeable buyers understand and anticipate this characteristic. It’s part of the accepted aesthetic within the craft.

- Authentic: These subtle marks are a hallmark of genuine handmade items, distinguishing them from mass-produced uniformity. They tell the story of the bead’s creation.

- Functional (Sometimes): In incense beads, slight porosity can actually aid in consistent burning or fragrance diffusion. In clay beads, some porosity affects the glaze fit and final character.

IV. When Pores Do Signal a Quality Problem: Context Matters

While generally normal, context is crucial. Pores can indicate issues in specific situations:

- Excessive Size or Quantity: A few small, shallow pores are normal. Large craters (exceeding 1-2mm diameter, depending on bead size), deep pits that threaten structural integrity, or a surface dominated by holes suggest potential problems:

- Poor Material Preparation: Insufficient mixing, incorrect binder ratio (too little or too much), or contaminated powder.

- Inadequate Forming Technique: Consistently insufficient compression during rolling.

- Improper Drying: Drying too fast or unevenly can cause excessive cracking and large voids.

- Associated with Structural Weakness: If the bead easily chips, cracks, or crumbles, especially from a pore, it indicates poor cohesion – likely due to material issues (wrong binder, old/contaminated powder) or severe under-compaction.

- In Specific Non-Powder Handmade Beads: While this answer focuses on powder beads, note:

- Glass Beads (Lampwork): Small bubbles can be a controlled artistic effect. However, large bubbles causing weak points or unintended excessive bubbles might reflect technique issues or impurities.

- High-Fire Ceramics (Stoneware/Porcelain): Glazed surfaces are expected to be smooth. Significant pitting under the glaze (pinholing) can be a firing defect. Pits in the glaze itself are usually a glaze flaw. Unglazed surfaces (like raku) will have inherent clay texture.

- Contamination: Pores filled with foreign material (dirt, debris not part of the intended mix) indicate contamination during production or handling, which is a quality control failure.

V. Assessing Quality in Handmade Powder Beads: Beyond the Surface

Quality assessment should focus holistically:

- Structural Integrity: Does the bead feel solid and durable? Does it hold together well without crumbling or cracking under gentle pressure? This is paramount.

- Overall Shape and Symmetry (if applicable): While hand-rolled won’t be geometrically perfect, is the shape pleasingly consistent and intentional? Does it function as intended (e.g., rolls smoothly if needed)?

- Color and Finish Consistency: Are colors blended as intended? Is any applied finish (oil, wax, light sealant) even and appropriate? Significant blotchiness or uneven finish might be an issue.

- Aroma (for Incense Beads): Is the scent pleasant, true to description, and of reasonable strength? This is a core functional quality.

- Craftsmanship Evidence: Are the beads cleanly made? Are rough edges smoothed? Is there care evident in the overall presentation? Minor pores don’t negate good craftsmanship elsewhere.

- Artist’s Intent: Does the artist describe their beads as having a rustic, natural, or textured aesthetic? If so, pores align with that intent.

VI. Communicating Value: Educating the Buyer

The key to managing expectations is proactive communication:

- Product Descriptions: Clearly state “handmade,” “naturally textured,” “may have slight surface variations,” or “characteristic minor pores.” Use close-up photos showing the actual texture, not just perfectly smooth stock images.

- Highlight the Craft: Explain the handmade process briefly – “Each bead is individually hand-rolled from [material], resulting in unique textures and subtle variations that are inherent to the artisanal process.”

- Reframe “Imperfection”: Use language like “organic texture,” “signs of handcrafting,” “natural character,” or “unique fingerprint.”

- Set Realistic Expectations: Avoid promising machine-level perfection if it’s not achievable through your process.

Embracing the Handmade Signature

The presence of small pits, pores, and slight surface irregularities in handmade powder beads is overwhelmingly not a sign of poor quality, but a testament to their authentic origin. It is the inevitable consequence of combining natural materials with the skilled, yet variable, human hand – the factor. These characteristics are fundamentally different from the flaws that plague mass-produced items.